The friction factor of galvanized pipe is

introduction

Abstract:

In this article, we will explore the friction factor of galvanized pipes from four different aspects. We will provide background information on galvanized pipes and discuss the importance of understanding their friction factors. By presenting detailed explanations and supporting evidence, we hope to shed light on the characteristics and behavior of galvanized pipe friction.

1. Introduction:

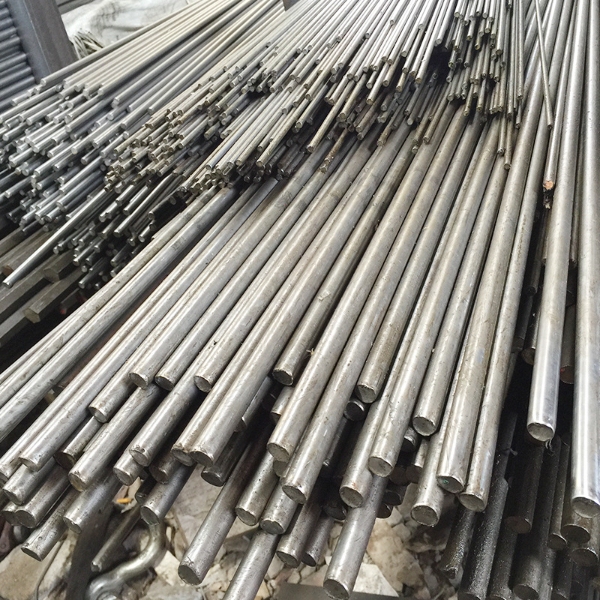

Galvanized pipes are widely used in various industries due to their excellent corrosion resistance and durability. However, understanding the friction factor of galvanized pipes is crucial for designing efficient and reliable fluid systems. This article aims to delve into the friction factor of galvanized pipes, providing valuable insights for engineers, researchers, and professionals in the field.

2. Factors Affecting Friction in Galvanized Pipes:

2.1 Surface Roughness:

The surface roughness of galvanized pipes plays a significant role in determining the friction factor. We will discuss the impact of different surface roughness on flow characteristics, including the effect of corrosion, scale deposition, and manufacturing processes.

2.2 Reynolds Number:

The Reynolds number, which represents the flow regime, greatly influences the friction factor. We will explore how the laminar and turbulent flow regimes affect the friction factor in galvanized pipes. Additionally, we will discuss the transitional region and its implications on the accuracy of friction factor estimation.

2.3 Pipe Diameter:

The diameter of the pipe has a notable influence on the friction factor. Large diameter galvanized pipes tend to exhibit different flow characteristics compared to small diameter pipes. We will explore the reasons behind these differences and discuss the practical implications for system design.

2.4 Fluid Properties:

Different fluids have varying viscosities and densities, which affect the friction factor in galvanized pipes. We will examine how fluid properties influence the flow resistance, and discuss the importance of accurately considering fluid characteristics in friction factor calculations.

3. Experimental Studies and Numerical Modeling:

To gain a comprehensive understanding of the friction factor of galvanized pipes, numerous experimental studies and numerical modeling approaches have been conducted. We will present the findings of some influential studies, highlighting their methodologies, results, and implications. Additionally, we will discuss the limitations of current research and potential areas for future investigation.

4. Conclusion:

In conclusion, the friction factor of galvanized pipes is a complex phenomenon affected by various factors such as  surface roughness, Reynolds number, pipe diameter, and fluid properties. Understanding these factors is essential for designing efficient fluid systems using galvanized pipes. By exploring the intricacies of galvanized pipe friction, this article provides valuable insights for engineers and researchers. Further research is needed to enhance our understanding and refine calculation methods for friction factors in galvanized pipes.

surface roughness, Reynolds number, pipe diameter, and fluid properties. Understanding these factors is essential for designing efficient fluid systems using galvanized pipes. By exploring the intricacies of galvanized pipe friction, this article provides valuable insights for engineers and researchers. Further research is needed to enhance our understanding and refine calculation methods for friction factors in galvanized pipes.

Example of article format:

Summary:

Galvanized pipes are widely utilized for their corrosion resistance, but understanding the friction factor is crucial. This article examines the factors influencing friction in galvanized pipes, including surface roughness, Reynolds number, pipe diameter, and fluid properties. Experimental and numerical studies provide insights into this complex phenomenon. By comprehending galvanized pipe friction, engineers can design efficient fluid systems. Further research is required to enhance calculation methods and broaden our understanding.

Leave a Comment