Production and processing methods of galvanized sheets

introduction

Production and Processing Methods of Galvanized Sheets

Abstract:

This article aims to provide an in-depth understanding of the production and processing methods of galvanized sheets. It will explore various aspects of galvanized sheet production and processing, including the galvanizing process, types of galvanized coatings, surface treatment, and quality control. By delving into these topics, readers will gain valuable insights into the production and processing techniques used in the galvanized sheet industry.

1. Galvanizing Process

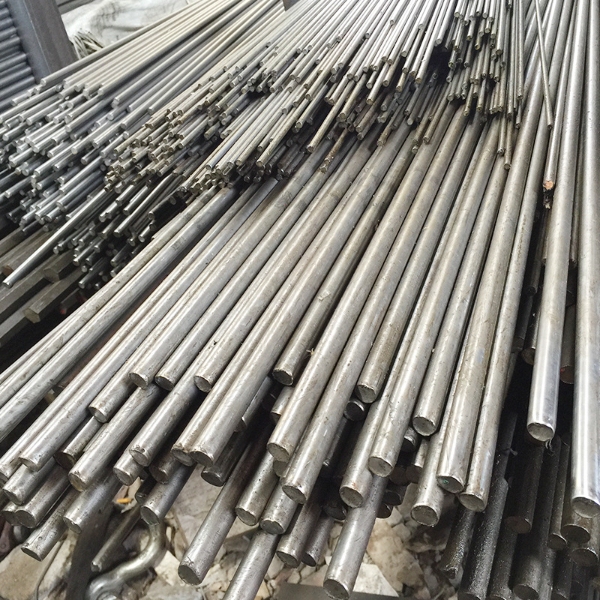

The galvanizing process is the core of galvanized sheet production and involves coating a steel sheet with a layer of zinc to protect it from corrosion. This section will depict the galvanizing process in detail, highlighting key stages such as surface preparation, zinc bath immersion, and post-treatment. Furthermore, it will discuss the importance of temperature control, dipping time, and zinc bath chemistry in achieving high-quality galvanized sheets.

2. Types of Galvanized Coatings

There are several types of galvanized coatings, each offering unique properties and applications. This section will explore three common types: hot-dip galvanizing, electrogalvanizing, and galvannealing. It will provide an overview of their processes, advantages, and disadvantages. Additionally, it will address the influence of coating thickness, adhesion, and uniformity on the performance of galvanized sheets.

3. Surface Treatment

Surface treatment plays a crucial role in the appearance and durability of galvanized sheets. This section will discuss various surface treatments, such as chromate conversion coating, phosphating, and passivation. It will examine the purpose of each treatment, its impact on the adhesion of paint or organic coatings, and the environmental considerations associated with different surface treatment methods.

4. Quality Control

Ensuring the quality of galvanized sheets is essential for meeting industry standards and customer requirements. This section will delve into the quality control processes used in the production and processing of galvanized sheets. It will cover topics such as coating thickness measurement, surface quality inspection, and corrosion resistance testing. Additionally, it will address the importance of adherence to international standards and the implementation of comprehensive quality management  systems.

systems.

Conclusion:

In conclusion, the production and processing methods of galvanized sheets involve a complex series of processes aimed at achieving high-quality and durable coatings. By understanding the galvanizing process, types of galvanized coatings, surface treatment, and quality control measures, industry professionals and researchers can enhance their knowledge and skills in this field. Additionally, it is crucial for manufacturers to prioritize adherence to international standards and invest in continuous research and development to drive innovation and improve the overall quality of galvanized sheets.

Leave a Comment