25mm galvanized pipe docking method

introduction

Abstract:

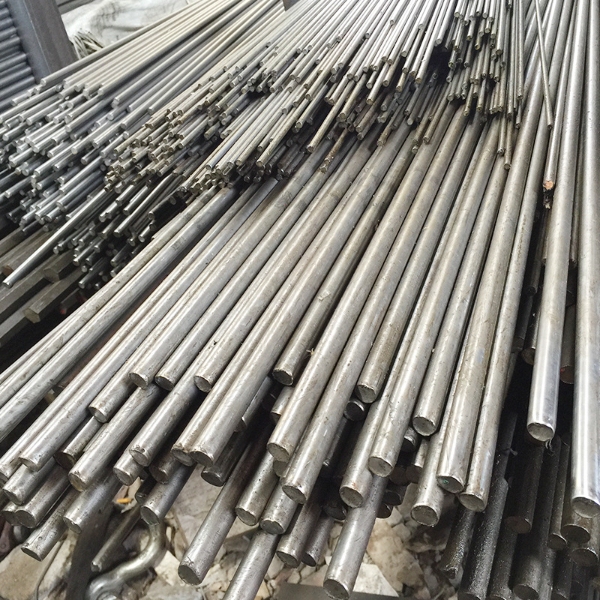

The 25mm galvanized pipe docking method is an essential process in various industries. This article aims to explore the different aspects of this method and its significance in practical applications. By examining the techniques, challenges, and advantages associated with the 25mm galvanized pipe docking method, this article provides an in-depth understanding of this important process.

1. Introduction

This section gives an overview of the 25mm galvanized pipe docking method, highlighting its relevance and importance in various industries. It provides background information on the significance of galvanized pipes and the need for proper docking methods.

2. Docking Techniques

2.1 Welding Technique

The welding technique for 25mm galvanized pipe docking involves the fusion of the pipe ends using heat. This section discusses the different welding techniques, such as arc welding and gas welding, along with their advantages and limitations. It also addresses the requirements for successful welding, including surface preparation, joint design, and proper inspection.

2.2 Mechanical Connection Technique

Mechanical connection techniques offer an alternative to welding for 25mm galvanized pipe docking. This section explores various mechanical connection methods, such as flanges and couplings, detailing their installation process, benefits, and limitations. It also highlights the importance of proper alignment and tightening in achieving a reliable connection.

2.3 Adhesive Bonding Technique

Adhesive bonding techniques provide a non-invasive method for 25mm galvanized pipe docking. This section discusses different types of adhesives used in the process and their application requirements. It also addresses the considerations for selecting appropriate adhesives based on factors like load-bearing capacity and environmental conditions.

2.4 Fastening Techniques

Fastening techniques play a vital role in securing the 25mm galvanized pipe docking. This section explores various fastening methods, such as bolts and screws, and their application in different scenarios. It highlights the importance of proper torque control and provides guidelines for selecting the right fasteners.

3. Challenges and Solutions

3.1 Corrosion Prevention

Galvanized pipes are susceptible to corrosion, which can affect the overall integrity of the docking.  This section discusses the challenges associated with corrosion prevention and presents effective solutions, such as protective coatings and cathodic protection systems.

This section discusses the challenges associated with corrosion prevention and presents effective solutions, such as protective coatings and cathodic protection systems.

3.2 Joint Strength and Durability

Ensuring the strength and durability of the docking is crucial for maintaining long-term structural integrity. This section addresses the challenges related to joint strength and durability and presents solutions like reinforcement techniques and quality control measures.

3.3 Compatibility with Different Materials

The 25mm galvanized pipe docking method often involves connecting galvanized pipes with different materials. This section examines the challenges in achieving compatibility and presents strategies to overcome them, including proper material selection and use of transition fittings.

4. Advantages and Applications

4.1 Cost Efficiency

The 25mm galvanized pipe docking method offers cost advantages compared to other techniques. This section discusses the factors contributing to cost efficiency, such as material availability, installation ease, and maintenance requirements.

4.2 Wide Range of Applications

The versatility of the 25mm galvanized pipe docking method allows its application in various industries. This section explores the diverse sectors where this method is used, including construction, plumbing, and infrastructure development.

4.3 Environmental Considerations

The environmental impact of the 25mm galvanized pipe docking method is a crucial aspect. This section discusses the eco-friendly characteristics of galvanized pipes and their contribution to sustainable development.

5. Conclusion

The 25mm galvanized pipe docking method is an integral part of various industries, and understanding its techniques, challenges, and advantages is essential for successful implementation. By comprehensively exploring these aspects, this article provides valuable insights and knowledge for professionals and researchers in this field. Further research on innovative docking methods and continuous improvement in surface protection will contribute to the development of this important process.

Leave a Comment