How to make galvanized sheets

introduction

How to Make Galvanized Sheets

Abstract:

This article aims to provide a comprehensive guide on how to make galvanized sheets. It will cover the process and key aspects involved in galvanizing sheets, as well as the benefits and applications of galvanized sheets. By exploring this topic, readers will gain a deeper understanding of galvanized sheets and their importance in various industries.

1. Introduction:

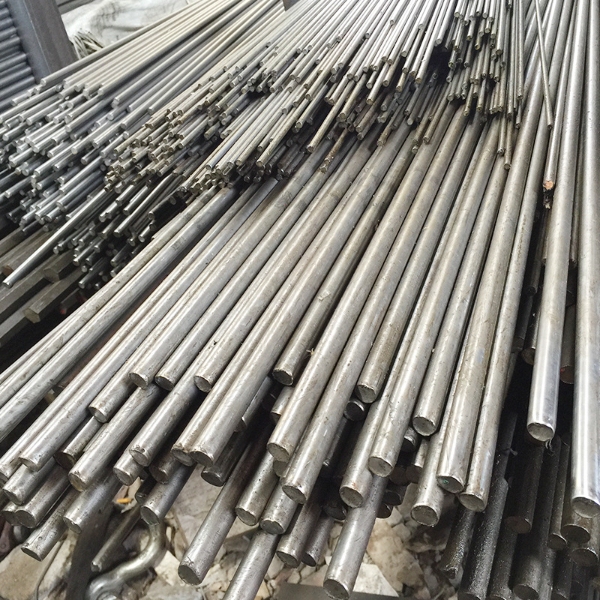

Galvanized sheets play a critical role in modern manufacturing and construction. Galvanizing, a process that involves coating steel or iron sheets with a protective layer of zinc, enhances their durability and corrosion resistance. In this section, we will delve into the background and significance of galvanized sheets, giving readers a context for the subsequent discussion.

2. The Galvanizing Process:

2.1 Hot-Dip Galvanizing:

Hot-dip galvanizing is the most common method for producing galvanized sheets. This section will walk readers through the step-by-step process, starting from surface preparation to the final product. It will highlight the key stages, such as degreasing, pickling, fluxing, and zinc coating, explaining their purpose and the techniques employed.

2.2 Electro-Galvanizing:

In addition to hot-dip galvanizing, electro-galvanizing is another popular technique for galvanizing sheets. Unlike the former, this method involves using an electric current to deposit a layer of zinc onto the steel or iron surface. This segment will elaborate on the process of electro-galvanizing, emphasizing its advantages, limitations, and specific applications.

2.3 Other Galvanizing Methods:

While hot-dip and electro-galvanizing are the predominant methods for galvanizing sheets, there are alternative techniques worth exploring. This section will shed light on these lesser-known methods, including sherardizing, mechanical plating, and continuous galvanizing. By providing a comprehensive overview, readers will gain insight into the diverse approaches available in the industry.

3. Benefits of Galvanized Sheets:

3.1 Corrosion Resistance:

Galvanizing sheets imparts remarkable corrosion resistance. This portion will delve into the chemical reactions that occur between the zinc coating and the environment, ultimately protecting the underlying metal from rust and erosion. It will also discuss the significance of corrosion resistance in various industries, from construction to automotive.

3.2 Longevity and Durability:

Galvanized sheets are known for their exceptional longevity and durability. By explaining the superior characteristics of zinc-coated sheets, such as their resistance to mechanical damage and weathering, this section will highlight why galvanized sheets are preferred in applications requiring extended service life.

3.3 Cost-Effectiveness:

Investing in galvanized sheets can yield cost savings over the long term. This segment will delve into the economic benefits associated with galvanized sheets, such as reduced maintenance and repair expenses. It will also discuss the life cycle cost analysis that demonstrates the financial advantages of galvanizing.

4. Applications of Galvanized Sheets:

4.1 Construction Industry:

The construction sector extensively relies on galvanized sheets for various purposes, ranging from structural components to roofing materials. This section will explore the specific applications of galvanized sheets in construction, emphasizing their advantages and contributions to the industry's growth.

4.2 Automotive Sector:

Galvanized  sheets find extensive use in the automotive industry due to their excellent corrosion resistance and formability. This portion will discuss the role of galvanized sheets in automobile manufacturing, including their applications in body panels, chassis, and other critical components.

sheets find extensive use in the automotive industry due to their excellent corrosion resistance and formability. This portion will discuss the role of galvanized sheets in automobile manufacturing, including their applications in body panels, chassis, and other critical components.

4.3 Other Industrial Applications:

Beyond construction and automotive, galvanized sheets have diverse applications in numerous industries. This section will shed light on these lesser-known uses, such as agriculture, manufacturing, and electrical engineering. By highlighting the versatility of galvanized sheets, readers will gain a broader perspective on their industrial significance.

5. Conclusion:

In conclusion, galvanized sheets have revolutionized modern manufacturing and construction with their exceptional qualities. From the galvanizing process to the benefits and applications, this article has thoroughly covered the topic, providing readers with valuable insights into galvanized sheets. By understanding the production and advantages of galvanized sheets, industries can make informed decisions for their specific needs, leading to more robust and durable products. As technologies evolve, future research may explore novel galvanizing techniques and further optimize the properties of galvanized sheets.

Leave a Comment