Strengthen anti-corrosion hot-dip galvanized pipe price

introduction

Strengthen Anti-Corrosion Hot-Dip Galvanized Pipe Price

Summary:

This article aims to delve into the topic of strengthen anti-corrosion hot-dip galvanized pipe price with the goal of providing readers with comprehensive information. By exploring various aspects, this article will shed light on the factors influencing the price of galvanized pipes and the importance of anti-corrosion measures in maintaining their longevity.

1. Factors Influencing Strengthen Anti-Corrosion Hot-Dip Galvanized Pipe Price

The price of strengthen anti-corrosion hot-dip galvanized pipes is influenced by a multitude of factors, which can broadly be categorized into four aspects: raw material costs, manufacturing processes, market demand, and government regulations.

Raw material costs play a significant role in determining the price of galvanized pipes. The price of steel, zinc, and other essential components directly affect production expenses. Fluctuations in these costs impact the final selling price of galvanized pipes. Furthermore, fluctuations in global commodity markets and geopolitical factors can exert additional pressure on raw material costs.

Raw material costs play a significant role in determining the price of galvanized pipes. The price of steel, zinc, and other essential components directly affect production expenses. Fluctuations in these costs impact the final selling price of galvanized pipes. Furthermore, fluctuations in global commodity markets and geopolitical factors can exert additional pressure on raw material costs.

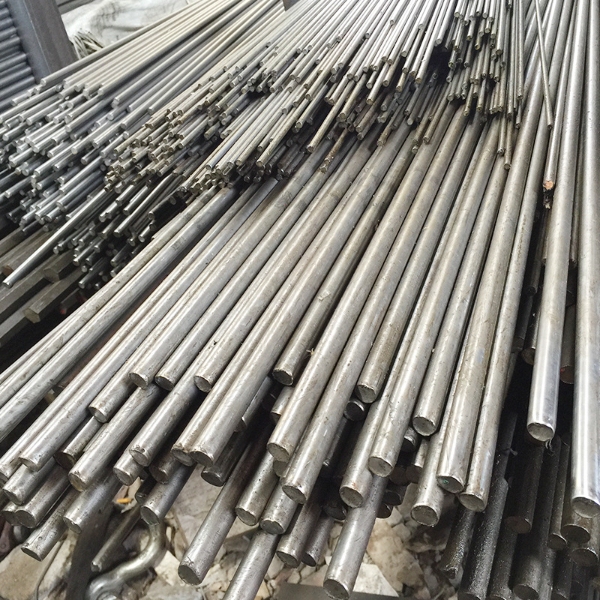

The manufacturing processes involved in producing strengthen anti-corrosion hot-dip galvanized pipes also contribute to their price. Advanced technologies and equipment used in the galvanization process enhance productivity and efficiency, leading to cost reduction. The choice of galvanizing methods, such as hot-dip and cold galvanizing, can also influence the final price.

Market demand is another crucial aspect that influences the price of galvanized pipes. Industries such as construction, infrastructure, and automotive heavily rely on galvanized pipes. Fluctuations in demand and supply chain dynamics can impact prices, especially during periods of high demand when supply struggles to meet requirements.

Government regulations impose certain standards and requirements on the production and quality of strengthen anti-corrosion hot-dip galvanized pipes. Compliance with these regulations incurs additional costs, which in turn impact the final selling price. Environmental regulations, workplace safety standards, and quality certifications are some examples of regulatory factors influencing the price.

2. The Importance of Anti-Corrosion Measures

Anti-corrosion measures are crucial in maintaining the longevity and durability of strengthen anti-corrosion hot-dip galvanized pipes. Corrosion is a natural process that can significantly degrade the integrity and functionality of pipes over time. By implementing effective anti-corrosion measures, the lifespan of galvanized pipes can be extended, reducing the need for frequent replacements and repair.

One of the most common anti-corrosion measures is the hot-dip galvanization process itself. This process involves coating the pipe with a layer of zinc, which acts as a sacrificial anode. Zinc sacrifices itself by corroding before the underlying steel, providing a protective barrier against oxidation. Regular inspection and maintenance can help identify any signs of corrosion and allow for timely repairs.

Additionally, applying protective coatings or paints can further enhance the anti-corrosion properties of strengthen anti-corrosion hot-dip galvanized pipes. These coatings provide an additional layer of protection against external factors such as moisture, chemicals, and atmospheric conditions. Proper installation practices and adherence to industry guidelines are also essential in preventing corrosion.

3. Conclusion

In conclusion, the price of strengthen anti-corrosion hot-dip galvanized pipes is influenced by various factors, including raw material costs, manufacturing processes, market demand, and government regulations. Understanding these factors is crucial for both manufacturers and consumers in making informed decisions.

Furthermore, the implementation of effective anti-corrosion measures is essential in preserving the longevity and durability of galvanized pipes. Regular maintenance, inspection, and the use of protective coatings can significantly reduce the risk of corrosion, resulting in cost savings and increased operational efficiency.

In the future, further research and development in anti-corrosion technologies and materials can contribute to the advancement of strengthen anti-corrosion hot-dip galvanized pipes. Increased collaboration between industry stakeholders, governments, and research institutions can help drive innovation and foster a sustainable and cost-effective solution for combating corrosion in galvanized pipes.

Leave a Comment