Non-standard galvanized pipe load-bearing

introduction

Non-standard Galvanized Pipe Load-Bearing

Abstract

This article aims to explore the concept of load-bearing in non- standard galvanized pipes. Non-standard galvanized pipes are a unique type of piping system that has gained popularity in various industries due to their numerous advantages. The article discusses the background and significance of non-standard galvanized pipes and highlights the importance of load-bearing capabilities in their design and usage. By providing a comprehensive overview of this topic, the article aims to enhance readers' understanding and generate interest in non-standard galvanized pipe load-bearing.

standard galvanized pipes. Non-standard galvanized pipes are a unique type of piping system that has gained popularity in various industries due to their numerous advantages. The article discusses the background and significance of non-standard galvanized pipes and highlights the importance of load-bearing capabilities in their design and usage. By providing a comprehensive overview of this topic, the article aims to enhance readers' understanding and generate interest in non-standard galvanized pipe load-bearing.

1. Introduction

1.1 Non-standard galvanized pipes: An overview

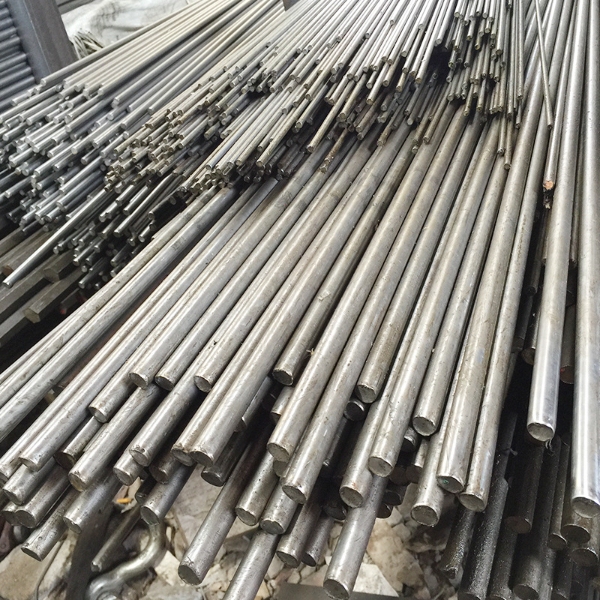

Non-standard galvanized pipes refer to custom-made pipes that deviate from standard specifications in terms of size, shape, or material. These pipes are widely used in different industries and applications due to their flexibility and adaptability.

1.2 Importance of load-bearing capabilities

Load-bearing capability is a crucial factor to consider when working with non-standard galvanized pipes. Ensuring that these pipes can withstand the required loads is essential for the safety and efficiency of various structures and systems.

1.3 Background and significance

The demand for non-standard galvanized pipes has been steadily increasing due to their unique properties. Understanding load-bearing capabilities in these pipes is essential for engineers, architects, and professionals involved in construction and infrastructure development.

2. Load-Bearing Design Considerations

2.1 Structural analysis of non-standard galvanized pipes

Before delving into load-bearing capabilities, it is essential to analyze the structural characteristics of non-standard galvanized pipes. This section provides an in-depth examination of the properties that make these pipes suitable for load-bearing purposes.

2.2 Load types and their effects on non-standard galvanized pipes

Different types of loads, such as static and dynamic loads, impact non-standard galvanized pipes differently. This section discusses the effects of various load types and their implications for load-bearing design.

2.3 Factors influencing load-bearing capacity

Several factors affect the load-bearing capacity of non-standard galvanized pipes. This section explores parameters like pipe material, wall thickness, diameter, and joint design, shedding light on their significance in determining the overall strength and structural integrity.

2.4 Load testing and evaluation methods

Validating the load-bearing capacity of non-standard galvanized pipes involves rigorous testing and evaluation procedures. This section introduces different testing methods and highlights their effectiveness in assessing the structural capabilities of these pipes.

3. Applications of Non-standard Galvanized Pipe Load-Bearing

3.1 Construction industry

Non-standard galvanized pipes find extensive applications in the construction industry, ranging from structural support systems to scaffolding. This section explores how load-bearing capabilities impact the design and implementation of these systems.

3.2 Industrial applications

Various industries, such as manufacturing, automotive, and chemical, utilize non-standard galvanized pipes for load-bearing purposes. This section provides insight into the specific applications and benefits within each industry.

3.3 Infrastructure development

Infrastructure projects, including bridges, tunnels, and pipelines, increasingly rely on non-standard galvanized pipes for load-bearing requirements. This section examines the advantages and challenges associated with implementing this piping system in infrastructure development.

4. Future Trends and Challenges

4.1 Advancements in non-standard galvanized pipe technology

The field of non-standard galvanized pipes is continually evolving, with advancements in materials, manufacturing techniques, and design. This section discusses emerging trends that could enhance the load-bearing capabilities of these pipes.

4.2 Environmental considerations

As sustainability becomes a significant concern, incorporating environmentally friendly practices in non-standard galvanized pipe load-bearing is crucial. This section explores potential challenges and solutions for creating more sustainable load-bearing systems.

4.3 Safety regulations and standards

Ensuring the safety of load-bearing structures requires adherence to strict regulations and standards. This section highlights the importance of complying with relevant guidelines and outlines potential challenges related to regulatory compliance.

5. Conclusion

In conclusion, non-standard galvanized pipe load-bearing holds immense potential for various industries and applications. Understanding the structural characteristics and load-bearing capabilities of these pipes is essential for designing safe and efficient structures. As advancements continue to shape the field, further research and innovation are necessary to unlock the full potential of non-standard galvanized pipe load-bearing. By staying abreast of emerging trends and considering environmental and safety concerns, professionals can harness the benefits of this piping system while ensuring sustainable and secure load-bearing structures.

Leave a Comment