Galvanized pipe outer perimeter

introduction

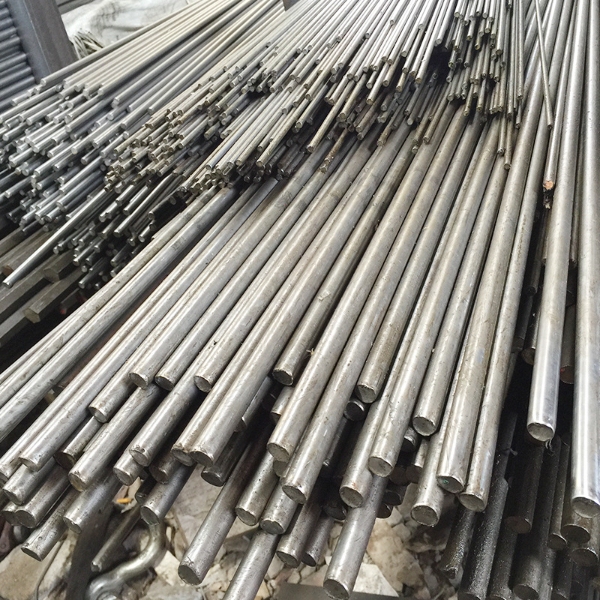

Galvanized Pipe Outer Perimeter: Protecting and Extending the Lifespan of Pipelines

Abstract:

This article aims to explore the significance and benefits of the galvanized pipe outer perimeter. By providing a comprehensive understanding of its features and advantages, readers can recognize the importance of incorporating galvanized pipe outer perimeters in pipeline systems. It also serves as a guide for professionals in the industry to make informed decisions regarding the installation and maintenance of pipelines.

Text:

1. The Importance of Galvanized Pipe Outer Perimeter

1.1 Protection Against Corrosion

Galvanized pipe outer perimeters play a vital role in safeguarding pipelines against corrosion. Corrosion is a natural process that occurs when metal comes into contact with the surrounding environment. With the implementation of galvanized pipe outer perimeters, pipelines are shielded from corrosive substances, such as moisture, salts, and chemicals. This protective layer effectively prevents the degradation of pipelines, extending their lifespan and ensuring their durability even in harsh conditions.

1.2 Enhanced Structural Integrity

The integration of galvanized pipe outer perimeters significantly enhances the structural integrity of pipelines. The galvanizing process involves coating the pipe with a layer of zinc, creating a barrier between the pipeline and the external elements. This additional layer strengthens the overall structure of the pipe, providing resistance against physical damage, impact, and heavy loads. As a result, pipelines with galvanized pipe outer perimeters exhibit improved performance, reducing the risk of leaks, ruptures, and other potential failures.

1.3  Cost-Effective Solution

Cost-Effective Solution

In terms of cost-effectiveness, galvanized pipe outer perimeters present a favorable option for pipeline installations and maintenance. The initial investment in galvanized pipes may seem slightly higher compared to conventional pipes; however, the extended lifespan and reduced maintenance requirements make them a wise choice in the long run. The protective zinc coating minimizes the need for frequent repairs and replacements, ultimately leading to cost savings over the life cycle of the pipeline system.

2. The Galvanizing Process and Quality Control

2.1 Galvanizing Process Overview

The galvanizing process involves a series of specific steps to ensure the effective corrosion protection of the pipe. Firstly, the pipe is thoroughly cleaned to remove any impurities or contaminants that could hinder the bonding of the zinc layer. Next, the pipe is dipped into a bath of molten zinc, creating a metallurgical bond between the zinc and the steel surface. Lastly, the galvanized pipe is cooled and inspected to verify the quality and consistency of the coating.

2.2 Quality Control Measures

To ensure the highest quality standards, strict quality control measures are implemented throughout the galvanizing process. Visual inspections are conducted to identify any defects, such as bare spots or excess zinc. Additionally, thickness measurements of the zinc coating are regularly performed to ensure it meets the specified requirements. These rigorous quality control measures guarantee that the galvanized pipe outer perimeter provides optimal protection and performance.

2.3 Advancements in Galvanizing Technology

With advancements in galvanizing technology, new methods and techniques have emerged to further improve the quality and efficiency of the galvanizing process. Continuous galvanizing, for example, allows for the continuous production of galvanized pipes, increasing production capacity and reducing costs. The introduction of alloyed zinc coatings has also enhanced the corrosion resistance of galvanized pipes, making them suitable for even the most challenging environments.

3. Case Studies: Applications and Success Stories

3.1 Oil and Gas Industry

In the oil and gas industry, the utilization of galvanized pipe outer perimeters has proven to be highly effective in preventing corrosion and ensuring safe operations. Pipelines carrying oil and gas can encounter aggressive environments, including high moisture, corrosive gases, and saltwater exposure. By integrating galvanized pipe outer perimeters, companies have witnessed a significant reduction in maintenance costs, as well as an overall increase in pipeline lifespan and reliability.

3.2 Water Distribution Networks

Water distribution networks, especially those exposed to various weather conditions, require durable and corrosion-resistant piping systems. Galvanized pipe outer perimeters have been successfully implemented in water distribution networks worldwide. The protection provided by galvanized pipe outer perimeters ensures clean water delivery, preventing contamination and minimizing the risk of leaks or pipe failures.

3.3 Infrastructure Development

The construction industry also benefits from the utilization of galvanized pipe outer perimeters in various infrastructure projects. From bridges to buildings, galvanized pipes offer structural stability and resistance against harsh environmental elements. The long lifespan and low maintenance requirements of galvanized pipes make them an ideal choice for large-scale infrastructure projects, providing a reliable and cost-effective solution.

Conclusion:

In conclusion, the incorporation of galvanized pipe outer perimeters is crucial to protect and extend the lifespan of pipelines. The benefits offered by galvanized pipe outer perimeters, such as corrosion protection, enhanced structural integrity, and cost-effectiveness, make them an indispensable component in pipeline systems. The galvanizing process, accompanied by strict quality control measures, ensures that these outer perimeters provide reliable and long-lasting performance. Through various case studies, the effectiveness of galvanized pipe outer perimeters in different industries has been demonstrated. The continuous advancements in galvanizing technology further enhance their capabilities. By embracing the utilization of galvanized pipe outer perimeters, industries can mitigate the risks associated with corrosion and enjoy sustainable and efficient pipeline systems for years to come.

Leave a Comment