Can electrical galvanized pipes be welded

introduction

Can Electrical Galvanized Pipes be Welded?

Abstract:

In this article, we will delve into the topic of whether electrical galvanized pipes can be welded. Welding is a widely used method in various industries, and understanding its feasibility with respect to electrical galvanized pipes is crucial. We will provide readers  with a comprehensive understanding of this subject, exploring various aspects such as the properties of electrical galvanized pipes, the welding process, potential challenges, and available solutions. By the end of this article, readers will have a clear understanding of the feasibility of welding electrical galvanized pipes.

with a comprehensive understanding of this subject, exploring various aspects such as the properties of electrical galvanized pipes, the welding process, potential challenges, and available solutions. By the end of this article, readers will have a clear understanding of the feasibility of welding electrical galvanized pipes.

1. Properties of Electrical Galvanized Pipes

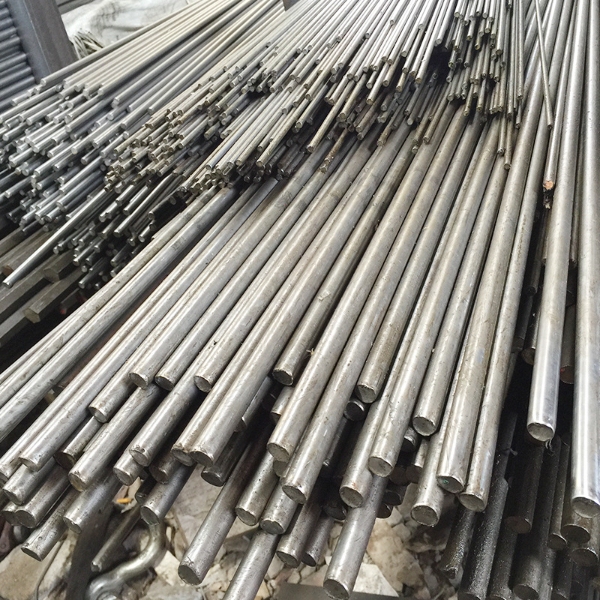

Electrical galvanized pipes are steel pipes that have been coated with a layer of zinc through an electroplating process. This coating provides excellent corrosion resistance, making electrical galvanized pipes popular in plumbing, construction, and other industries. However, the zinc coating presents challenges when it comes to welding. The high melting point of zinc requires careful consideration during the welding process to avoid compromising the pipe's integrity.

2. The Welding Process

Welding electrical galvanized pipes requires adequate preparation and knowledge. The first step is to remove the zinc coating around the intended weld area. This can be done by mechanical means or through chemical methods. Once the coating is removed, the pipes can be welded using various welding techniques such as arc welding, MIG welding, or TIG welding. Each technique has its advantages and considerations, and welders must choose the most suitable method based on the specific application and requirements.

3. Challenges and Solutions

Welding electrical galvanized pipes poses several challenges that need to be addressed to ensure a successful weld. One major challenge is the potential for the formation of zinc oxide fumes during the welding process. These fumes can be harmful if inhaled, so proper ventilation and personal protective equipment are essential. Additionally, the heat input during welding can distort the pipes or cause burn-through. Controlling the heat input and using specialized welding techniques can mitigate these issues. It is also important to note that the welds on electrical galvanized pipes might not be as visually appealing as on bare steel due to the presence of the zinc coating.

4. Advantages and Disadvantages

Welding electrical galvanized pipes may have certain advantages, such as maintaining the corrosion resistance properties of the pipes after welding. Additionally, electrical galvanized pipes are readily available and cost-effective. However, there are also disadvantages to consider. The welding process may weaken the zinc coating, reducing the overall corrosion resistance of the pipes. It is crucial to carefully assess the application and potential risks before deciding to weld electrical galvanized pipes.

Conclusion:

In conclusion, while it is feasible to weld electrical galvanized pipes, it requires careful consideration and adherence to proper procedures. Understanding the properties of electrical galvanized pipes, the welding process, and potential challenges is essential for successful welding. By following appropriate techniques, utilizing adequate safety measures, and being aware of the advantages and disadvantages, welders can confidently weld electrical galvanized pipes. It is recommended to consult with experts and refer to industry standards to ensure the best outcomes.

Leave a Comment