Galvanized steel tie national standard thickness

introduction

Galvanized Steel Tie National Standard Thickness

Abstract:

The topic of galvanized steel tie national standard thickness is undoubtedly an important and fascinating one. In this article, we delve into the depths of this subject, providing readers with background information and shedding light on the significance of galvanized steel tie thickness in various applications. By exploring the four key aspects of galvanized steel tie national standard thickness, we aim to ensure that our readers gain a comprehensive understanding of this crucial topic.

Text:

1. Importance of Galvanized Steel Tie Thickness

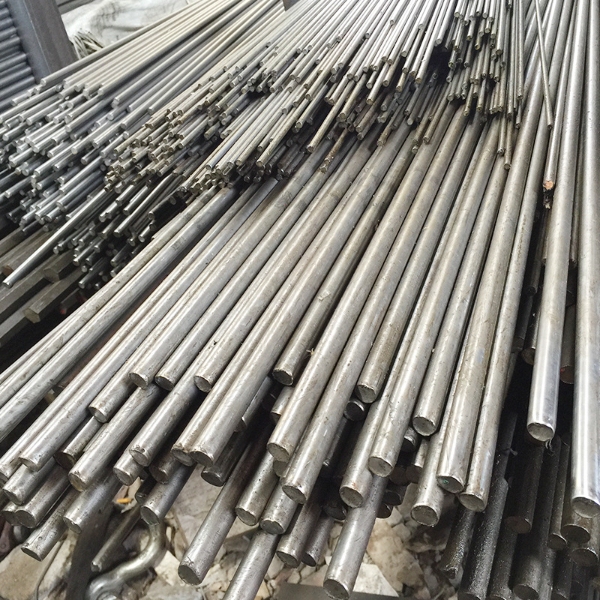

Galvanized steel ties play a crucial role in various industries such as construction, infrastructure, and manufacturing. One of the fundamental aspects of galvanized steel tie quality is its thickness, as it determines the structural integrity and durability of the ties in different applications. In this section, we will highlight the importance of galvanized steel tie thickness and its influence on the overall performance and longevity of the ties.

The thickness of galvanized steel ties is an integral factor in their ability to resist corrosion and withstand environmental factors. With thicker coats of zinc, galvanized steel ties have a higher level of protection against rust and other forms of degradation. This, in turn, ensures the longevity and reliability of the ties, making them an ideal choice for critical applications.

Furthermore, the thickness of galvanized steel ties directly impacts their tensile strength. Ties with greater thickness exhibit enhanced load-bearing capacity, making them suitable for heavy-duty applications in construction and infrastructure projects. By exploring the optimal thickness requirements for galvanized steel ties, we can ensure that these ties meet the national standards and provide the required level of strength and reliability.

In addition to corrosion resistance and strength, galvanized steel tie thickness also affects the ease of installation and maintenance. Ties with appropriate thickness are easier to handle during installation, reducing the risk of damage or breakage. Similarly, maintenance becomes more convenient when ties possess the right thickness, allowing for efficient inspection and repair.

2. National Standards and Regulations

1. Evolution of Galvanized Steel Tie Standards

Over the years, national standards and regulations for galvanized steel tie thickness have evolved to meet the changing needs of industries. This section explores the historical development of these standards, highlighting key milestones and revisions that have shaped the present-day requirements.

Initially, the focus of galvanized steel tie standards was primarily on the thickness of the zinc coating. As the importance of galvanized steel tie thickness in structural integrity became apparent, further advancements were made to establish national standards dedicated to the thickness aspect. These standards continue to evolve, incorporating new research findings and technological advancements to ensure the optimal performance and reliability of galvanized steel ties.

Taking into account factors such as load bearing capacity, environmental conditions, and installation requirements, national standards have established specific guidelines for galvanized steel tie thickness. These standards serve as a crucial reference for manufacturers, engineers, and regulatory bodies, ensuring that galvanized steel ties meet the necessary requirements for safety and performance.

2. Implementation and Compliance

Implementing and ensuring compliance with national standards for galvanized steel tie thickness is crucial for maintaining safety and quality. In this section, we explore the processes and mechanisms involved in implementing these standards, as well as the measures taken to ensure compliance.

The implementation of national standards for galvanized steel tie thickness involves collaboration between manufacturers, regulators, and quality control organizations. Manufacturers must adhere to specific processes and guidelines to ensure the desired thickness of the galvanized steel ties. Quality control organizations play a vital role in carrying out tests and inspections to verify compliance with the established standards.

Compliance with national standards is ensured through rigorous inspections, certifications, and audits. Regulators and third-party organizations conduct periodic assessments to verify that galvanized steel ties meet the prescribed thickness requirements. Non-compliance can lead to penalties, recalls, and even legal implications, highlighting the importance of adhering to these standards.

3. Industry Applications and Implications

1. Construction Industry

The construction industry heavily relies on galvanized steel ties, and the thickness of these ties is of utmost importance. In this section, we explore the application of galvanized steel ties in construction and delve into the implications of their thickness in different construction projects.

The thickness of galvanized steel ties determines their load-bearing capacity, making them suitable for applications such as scaffolding, formwork, and structural support systems. The ability of these ties to withstand heavy loads and environmental conditions depends on their thickness, ensuring a safe and durable construction process.

By adhering to national standards for galvanized steel tie thickness, construction companies can ensure compliance with safety regulations and improve the overall quality of their projects. Properly selected and installed galvanized steel ties, with the right thickness, enhance the structural integrity and longevity of buildings, bridges, and other infrastructure projects.

2. Manufacturing and Industrial Applications

Galvanized steel ties also find extensive use in manufacturing and industrial applications, and their thickness is a crucial parameter in these sectors. This section focuses on the applications of galvanized steel ties in manufacturing and explores how their thickness affects product quality and performance.

From automotive manufacturing to electrical appliances, galvanized steel ties with specific thicknesses serve various purposes. The thickness of these ties plays a critical role in ensuring product safety, longevity, and reliability. Industries adhere to national standards for galvanized steel tie thickness to maintain uniformity and meet the necessary quality requirements.

By understanding the implications of galvanized steel tie thickness in various manufacturing and industrial applications, businesses can make informed decisions regarding the selection and use of these ties. Proper thickness ensures that products endure harsh conditions, resist corrosion, and maintain their intended functionality, contributing to customer satisfaction and overall success.

3. Other Utilizations and Emerging Trends

Beyond construction and manufacturing, galvanized steel ties have various other utilizations and are subject to evolving trends in their thickness requirements. In this section, we discuss emerging trends in galvanized steel tie thickness and how they impact sectors such as telecommunications, agriculture, and renewable energy.

Telecommunications infrastructure, for instance, relies on galvanized steel ties for cable management and support structures. The thickness requirements in this sector are influenced by factors such as load-bearing capacity, protection against environmental elements, and the need for easy maintenance.

The agriculture sector has also recognized the benefits of galvanized steel ties in applications such as vineyards, trellises, and greenhouse structures. The appropriate thickness of these ties ensures their durability and stability in outdoor environments, contributing to the efficiency and productivity of agricultural operations.

Furthermore, as the world shifts towards renewable energy sources, galvanized steel ties play a vital role in supporting solar panels, wind turbines, and other renewable energy infrastructure. The thickness of these ties is crucial for withstanding the elements and ensuring the  long-term performance of renewable energy systems.

long-term performance of renewable energy systems.

4. Conclusion

The importance of galvanized steel tie national standard thickness cannot be overstated. In this article, we have explored the significance of galvanized steel tie thickness in various sectors, including construction, manufacturing, telecommunications, agriculture, and renewable energy. By adhering to national standards, businesses can ensure the quality, safety, and reliability of galvanized steel ties in their respective applications.

In conclusion, galvanized steel tie national standard thickness is a critical aspect that deserves careful attention. It influences the durability, load-bearing capacity, and corrosion resistance of galvanized steel ties. By understanding and implementing the appropriate standards, industries can harness the full potential of galvanized steel ties and reap the benefits of these versatile and essential components. Continuous research and innovation in galvanized steel tie thickness will pave the way for future advancements in multiple industries, ensuring a safer, more sustainable, and efficient future.

Leave a Comment