How to connect galvanized steel

introduction

How to Connect Galvanized Steel: Step-by-Step Guide

Abstract:

This article provides a comprehensive guide on how to connect galvanized steel. It aims to educate readers about the various methods and techniques involved in connecting galvanized steel, highlighting the importance of this process in construction and industrial applications. Readers will gain a deeper understanding of the subject and be equipped with the knowledge to successfully connect galvanized steel in their own projects.

1. Welding Galvanized Steel

1.1 Understanding the Galvanizing Process

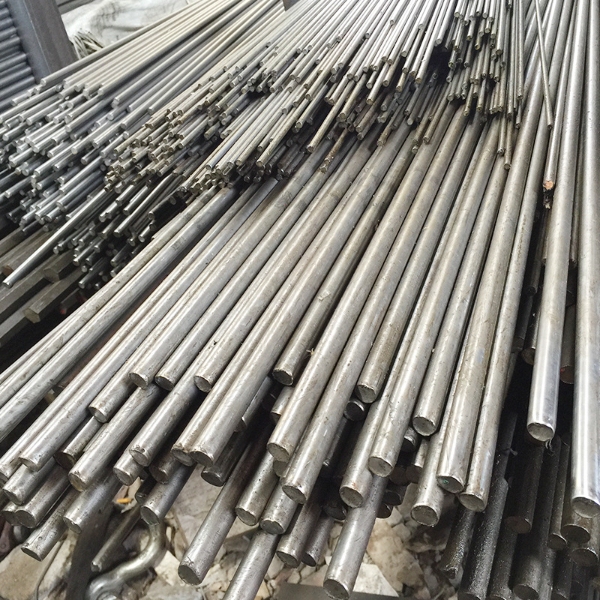

Galvanizing is a protective coating applied to steel to prevent corrosion. Before welding galvanized steel, it is crucial to understand the galvanizing process. This section delves into the details of galvanizing, including its purpose, benefits, and potential challenges.

1.2 Preparing Galvanized Steel for Welding

Proper preparation is essential for successful welding of galvanized steel. This subsection covers the necessary steps for preparing galvanized steel, such as cleaning, removing the zinc coating, and using special welding techniques to minimize damage and ensure strong welds.

1.3 Welding Techniques for Galvanized Steel

Welding galvanized steel requires specific techniques to maintain the integrity of the steel and its galvanized coating. This section explores different welding techniques commonly used for galvanized steel, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Each technique's advantages, limitations, and best practices are discussed in detail.

1.4 Post-Welding Considerations

After welding galvanized steel, additional steps must be taken to ensure its long-term durability. This subsection examines post-welding considerations, such as zinc-rich paint application, inspection for potential defects, and proper handling and storage to prevent damage to the galvanized coating.

2. Mechanical Fastening of Galvanized Steel

2.1 Types of Mechanical Fasteners

Mechanical fastening offers an alternative to welding for connecting galvanized steel. This section presents various types of mechanical fasteners commonly used in construction and industrial applications, including bolts, screws, rivets, and clips. Each type's characteristics, installation procedures, and factors to consider are thoroughly explained.

2.2 Design Considerations for Mechanical Fastening

Proper design plays a crucial role in the successful mechanical fastening of galvanized steel. This subsection discusses important design considerations, such as joint configurations, load-bearing capacity, and the effect of galvanized coating on fastener performance. Emphasis is placed on designing robust connections capable of withstanding stress and preventing premature failure.

2.3 Installation Techniques for Mechanical Fasteners

Installing mechanical fasteners in galvanized steel requires precision and adherence to specific techniques. This section provides step-by-step instructions for installing different types of fasteners, highlighting best practices, torque values, and recommended tools and equipment. It also addresses potential challenges, such as thread galling and corrosion prevention.

2.4 Maintenance and Inspection of Mechanical Connections

Regular maintenance and inspection are crucial for ensuring the integrity and reliability of mechanical connections in galvanized steel structures. This subsection outlines key maintenance practices, such as periodic tightening of fasteners, inspection for signs of corrosion or degradation, and prompt repairs if necessary. It emphasizes the importance of proactive maintenance to prevent costly failures.

3. Adhesive Bonding of Galvanized Steel

3.1 Types of Structural Adhesives

Adhesive bonding offers a versatile and efficient method for connecting galvanized steel. This section introduces different types of structural adhesives suitable for bonding galvanized steel, such as epoxy, polyurethane, and acrylic adhesives. It discusses their properties, curing mechanisms, and considerations for  specific applications.

specific applications.

3.2 Surface Preparation for Adhesive Bonding

Proper surface preparation is critical for achieving strong and durable adhesive bonds with galvanized steel. This subsection explains the importance of cleaning, degreasing, and roughening the galvanized surface to enhance adhesion. It also discusses the use of primers and surface activation techniques to optimize bond strength.

3.3 Application Techniques for Adhesive Bonding

Applying adhesive to galvanized steel requires precise techniques to ensure reliable bond formation. This section provides detailed instructions on adhesive application, including mixing ratios, open time, and cure cycles. It also addresses common challenges, such as adhesive shrinkage and debonding prevention.

3.4 Testing and Quality Assurance of Adhesive Bonds

Validating the quality and reliability of adhesive bonds is essential to ensure the structural integrity of galvanized steel connections. This subsection discusses various non-destructive and destructive testing methods, such as peel tests, shear tests, and environmental exposure tests. It emphasizes the importance of proper testing protocols and adherence to industry standards.

Conclusion:

In conclusion, connecting galvanized steel encompasses various methods, each with its advantages, limitations, and considerations. Whether through welding, mechanical fastening, or adhesive bonding, the key is to understand the galvanizing process, properly prepare the surfaces, and follow industry best practices. Successful connections not only ensure structural integrity but also maximize the longevity and performance of galvanized steel structures. By applying the knowledge gained from this article, readers will be well-equipped to connect galvanized steel effectively in their projects, contributing to the advancement of construction and industrial applications.

Leave a Comment